Tonight, we got some interesting information to help you optimize your inventory process. That includes optimal inventory benefits, the finest inventory tools, and the best practices for upping your stocking game.

BIG IDEA

🦸 Inventory management (IM) is the unsung hero of business success. Optimizing stock levels not only improves the overall flow of your business but also avoids pitfalls that would disappoint customers, such as stockouts.

But with all the hustle and bustle, doing so is easier said than done. Fortunately, Pacvue shares how you can do the right calculations to steer clear of overstocking.

🤫 The secret formula to optimal inventory

Excess inventory can be a strategic move for risk reduction, especially during unexpected supplier delays. But too much excess can eat into profits.

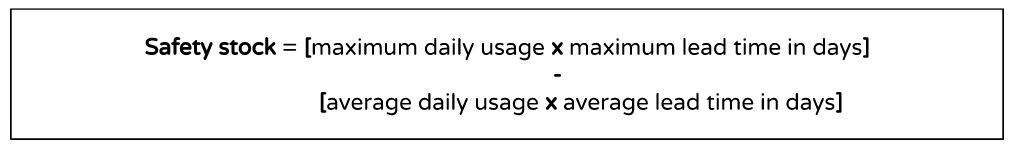

So, in general, a low excess inventory rate is desirable. Setting your safety stock to around 10% or less of your inventory would be best. But if you want a specific number, here's how you can calculate your safety stock:

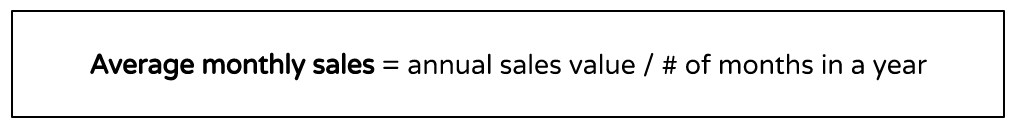

- Determine your average monthly sales for each product.

- Then, calculate the safety stock by using the safety stock formula. The maximum and average lead times are the longest and average times it takes your supplier to deliver your orders, respectively.

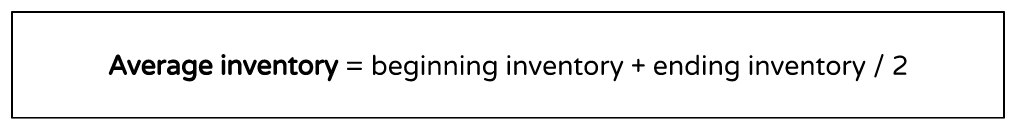

But IM doesn't end here. Once you know your numbers, the next step is to control them. For instance, you can track your average inventory to balance your supply and demand perfectly. Here's how:

🔢 There's power in numbers

After you've diligently crunched the numbers, it's time to leverage this knowledge to your advantage. There are 6 ways you can make the most of them:

- For regular inventory monitoring. This will keep you one step ahead of overstocking/understocking problems.

- For optimizing your ordering frequency. The numbers would help you align your orders with your sales pace.

- For planning the best promotions and discounts. Knowing how much you can salvage through enticing promotions and discounts would save your business from losses caused by non-moving inventory.

- For disposing of excess inventory. You can explore responsible ways to get rid of them, such as joining Amazon's DBA liquidation and FBA Grade and Resell programs, donating to charitable organizations, trading with other retailers, or returning them to suppliers.

- For pricing your products competitively. And avoiding overpricing, as well.

- For exploring alternative fulfillment options. Mastering how to manipulate your inventory will allow you to diversify your income channels by trying on other platforms' fulfillment methods.

🥅 The ultimate goal: satisfied customers

All the benefits of IM ultimately lead you toward this target. You see, monitoring your inventory levels allows you to make data-driven decisions for your business. And once you know your ideal stock level and reorder point (ROP), your customers will surely get their orders on time.

The bottom line is excess inventory won't be a problem as long as you're in control. To do that, you'd have to be smart and agile. If there's one type of excess that's good, that would be excess business success.

HOT TOPIC

Excel vs. software: Best tool for inventory management?

When dealing with inventory, you can go about it in two ways—manual or automatic. Keeping track of inventory manually is ideal if you have a small number of items to work with. But as you scale, it may be hard to consolidate things this way.

💻 So now we move to automation, which will be our main focus for today. But which of the available automated methods is your best bet?

Today, we'll compare the trusty old Excel and inventory management software (extending further to AI-drivel tools). Here's how they par up to one another, as written by MakeUseOf:

📝 Excel

Think of this as a sophisticated manual spreadsheet. But it goes way beyond basic arithmetic. It already has templates and features for project management, accounting, and forecasting.

- Why we love it: It's an economical option. Almost all Microsoft Office suites now offer this in their packages, and it usually comes for free upon signing up. Google Sheets or other online spreadsheets may also be a good alternative.

- Why consider something else: Although it's a more advanced spreadsheet, it's still time-consuming when working with large amounts of data. It also lacks automation for those repetitive methods, which isn’t ideal if you want to maximize efficiency.

🖩 Inventory management software

Some of the most popular ones are Zoho, Cin7 Orderhive, Oracle, and Quickbooks. These were truly a game changer since these are specifically made for inventory management.

Unlike Excel, which was made for general use, this type of software has input fields and other features directly related to managing inventory.

- Why we love it: You can easily integrate this into the other departments of your business, such as sales and shipping. This is ideal if you’re managing a lot of items or you have inventories stored in different places. Automation reduces human error, so this will save you time and give you the most accurate data.

- Why consider something else: They come with a price! Plus, some have steep learning curves that you have to first teach your team so they can fully maximize its capabilities.

Some software already incorporates AI-driven tools into their systems. Its goal is to reduce the number of manual processes, which could further increase efficiency and accuracy. AI can provide support in these ways:

- Automatically order plans

- Help pacify supplier unpredictability

- Increase accuracy for inventory and demand forecasting

- Minimize overstock and stockouts

Which one's better?

As you scale, investing in an inventory management system should be one of your business goals. Its features can justify the possible hefty price that comes with it.

But if you're still starting out, don't feel pressured to invest in sophisticated software immediately! Starting small with Excel or Google Sheets would suffice until your needs say otherwise.

BITES OF THE WEEK

- As inflation continues to force down consumers’ spending, you need a ‘hero’ to ensure your business survives. Well, warehouse management could be your savior. - Supply & Demand Chain Executive

- UPS is hailed as the largest transportation corporation of 2022. And by August 2023, it could bag another ‘biggest’—biggest work stoppage due to disputes over employees’ pay and benefits. - The Washington Post

- Shipping speed is what puts Amazon above the rest of the ecommerce players. So to maintain its edge, the retail giant is planning to overhaul its delivery network. - Supermarket News

- As we said, warehouse management could be the answer to your business woes. For starters, it can smoothen out the flow of goods from you to your customers. - Solutions Review

- But of course, optimizing your inventory and warehouse processes won’t be possible without accurate demand forecasting. In fact, the latter can be the long-term solution to your business concerns. - Maersk

ACTIONABLE ADVICE

7 best practices for managing inventory and supply chain

With fee hikes and price increases left and right, finding sustainable IM practices is a must. They don’t have to be big, costly steps—just smart. 💡

And who else can give you proven tricks other than Amazon itself? Here are 7 small but effective practices from the retail giant to achieve a smooth-flowing supply chain:

⚒️ Build and maintain healthy supplier relationships

As your major partner, any conflict with your suppliers can mess up your inventory big time. It’s important to build rapport with them by paying on time, communicating clearly, and treating each other with respect.

🔎 Monitor your sell-through rate (STR)

STR tells how quickly you sell inventory within a set time. The higher STR, the better.

To make sure you have a healthy STR, pay attention to the balance of outgoing and incoming products. It would help to use forecasting tools when you place your orders to avoid overstocking.

💯 Regularly restock popular products

This one’s self-explanatory. Not all your products will sell at the same time, so the rule is to restock your fast-selling items first.

🏷️ Move aging inventory via promotions

Let’s put it this way: Avoid paying extra storage fees by discounting old stocks.

📈 Track your operating costs

As we said, fees are everywhere—from ordering items to shipping, storage, and order fulfillment. But being a smart budgeter would effectively steer you away from them. The first step: track your cash flow so you never go over budget.

💲 Do not overstock

Aside from preventing excess inventory, it’ll help you avoid sunk costs. Your stock should just be enough to meet demand and maintain profitability.

Ideally, your buffer inventory should cover four weeks. This will give you wiggle room in case unexpected things arise.

🖥️ Use an inventory software

And choose the best one for your business. By best, we mean all-around and easy-to-use inventory tools. This way, you can streamline the tracking and monitoring of your inventory.

⚪ These tips are general guidelines to stay on top of your inventory. But the specific actions would still depend on your actual situation.

So, which of these would you be trying soon? Let us know if you want to add more tips by replying to this email.